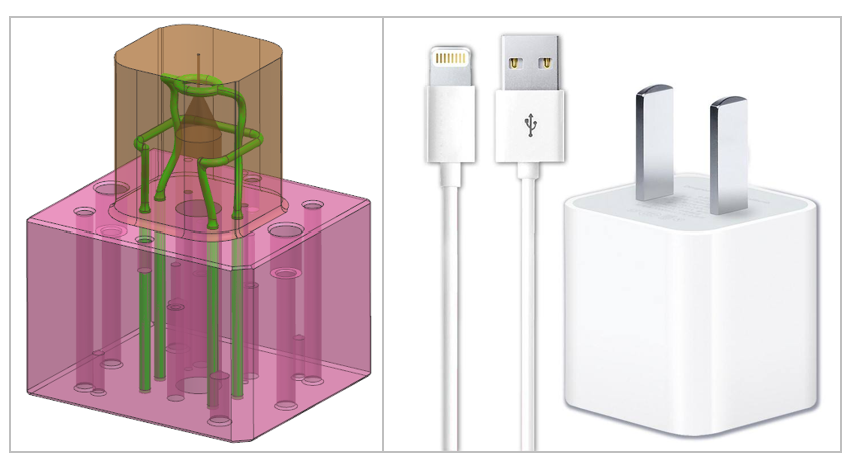

In the highly competitive consumer electronics market, manufacturing speed and part quality are the two most critical factors for success. A recent case study focusing on a cell phone charger housing demonstrates how advanced mold cooling technologies—specifically Conformal Cooling—are revolutionizing production by slashing cycle times and eliminating defects.

The Challenge: Traditional Cooling Bottlenecks

Standard injection molds use straight-drilled cooling channels. While cost-effective to manufacture, these channels cannot follow the complex curves of a charger case. This leads to:

-

Thermal Hotspots: Heat trapped in corners and deep cavities.

-

Uneven Cooling: Different sections of the part solidify at different rates.

-

Warpage and Sink Marks: The primary cause of “scrap” or rejected parts.

The Solution: Conformal Cooling & DIDO Systems

To overcome these hurdles, engineers implemented Conformal Cooling channels created through metal 3D printing (DMLS). These channels “conform” to the part’s geometry, maintaining a uniform distance from the cavity surface.

The case study specifically highlights the Dual-Inlet Dual-Outlet (DIDO) configuration. Unlike a single-circuit system, DIDO provides:

-

Independent Flow Control: Allows for precise temperature regulation in two separate zones of the mold.

-

Increased Heat Extraction: Two inlets mean more coolant volume can pass through the mold at once, carrying away heat faster.

-

Balanced Thermal Profile: Reduces the temperature gradient across the mold surface to near-zero.

Why This Matters for Your Business

The shift to conformal cooling isn’t just a technical upgrade; it’s a financial one.

1. Increased Throughput

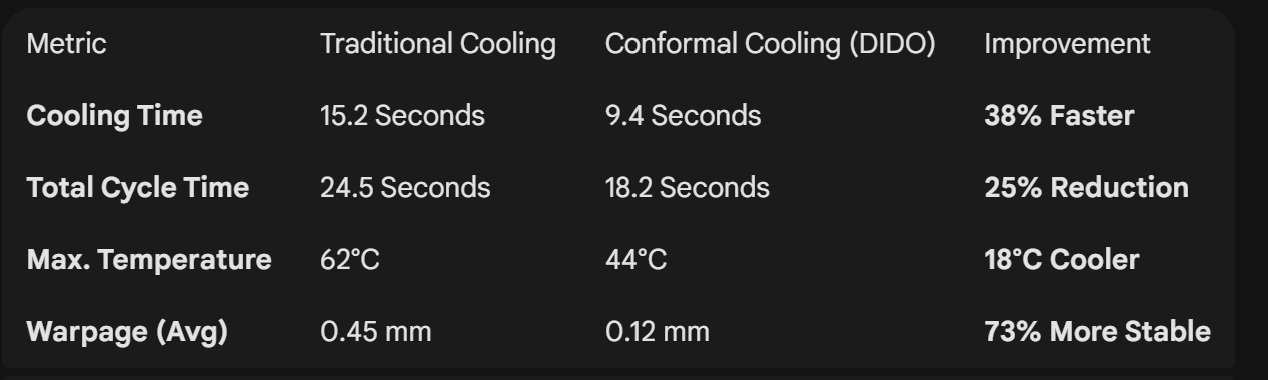

Reducing a cycle time by just 6 seconds might seem small, but in a 24/7 high-volume production run of 1 million units, it equates to hundreds of extra hours of production capacity per year without adding a single machine.

2. Superior Part Quality

By maintaining a consistent 44°C across the mold, the charger cases produced are structurally sound and visually perfect. This eliminates the need for post-production straightening and significantly lowers the scrap rate.

3. Lower Energy Costs

Efficient heat extraction means the chilling units don’t have to work as hard to maintain mold temperatures, leading to lower utility costs over the life of the tool.

Conclusion: Is Conformal Cooling Right for You?

While the initial cost of a 3D-printed mold insert is higher than a traditionally machined one, the Return on Investment (ROI) is typically achieved within the first few months of production. For complex consumer electronics like cell phone chargers, the benefits of DIDO Conformal Cooling are undeniable.

If you would like us to assist you in cost reduction and increase production efficiency, contact us at info@glasfil.com or chat with us here.